5-AXIS CNC MACHINE

5 AXIS CH Series

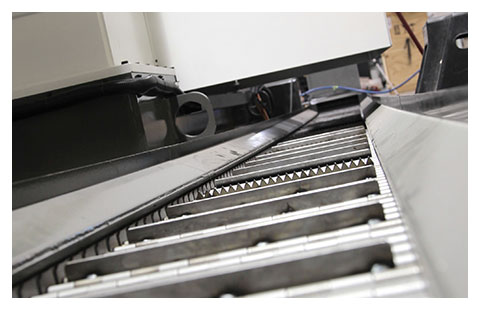

The Compact High Rail, or CH Series for short, CNC machining center is based on a heavy, one-piece, engineered (thick-walled) steel base with internal steel reinforcements, thus forming a machine bed engineered to handle the extreme weights of large blocks of materials you'll be throwing at it. The massive moving bridge provides over three foot of bearing spacing which offers substantial leverage over the part. Spanning the stationary support walls (and supported by heavy-gauge steel), the dual ball-screw drive mechanisms deliver smooth, fast, precise, and back-lash free motion of the bridge as well. All electronics and mechanical drives are located completely outside of the machining envelope to prevent potential contamination associated with either wet or dry machining. The addition of internal perimeter walkways and optional retractable roof bellows allow for ease of material loading and part unloading. The redesign results in a roomier cutting envelope – more power, rigidity and accuracy – and the ability to machine large block or plate raw materials within an enclosure. The new 5-Axis CH Series by C.R. Onsrud is a serious CNC machine for serious manufacturing applications.

The Compact High Rail, or CH Series for short, CNC machining center is based on a heavy, one-piece, engineered (thick-walled) steel base with internal steel reinforcements, thus forming a machine bed engineered to handle the extreme weights of large blocks of materials you'll be throwing at it. The massive moving bridge provides over three foot of bearing spacing which offers substantial leverage over the part. Spanning the stationary support walls (and supported by heavy-gauge steel), the dual ball-screw drive mechanisms deliver smooth, fast, precise, and back-lash free motion of the bridge as well. All electronics and mechanical drives are located completely outside of the machining envelope to prevent potential contamination associated with either wet or dry machining. The addition of internal perimeter walkways and optional retractable roof bellows allow for ease of material loading and part unloading. The redesign results in a roomier cutting envelope – more power, rigidity and accuracy – and the ability to machine large block or plate raw materials within an enclosure. The new 5-Axis CH Series by C.R. Onsrud is a serious CNC machine for serious manufacturing applications.

STANDARD FEATURES

4-Pole, reversible, 22,000 RPM High Torque Spindle

HSK-63F Spindle Taper and Tool Holders, with 1 inch (25mm) collet capacity

Over 24 Inches of Z-Axis Clearance & 29 inches of Z-Axis stroke standard

Finite Element Analysis used Extensively in the Engineering Process

Thermal Heat Treated, Stress Relieved, & Normalized One-Piece Steel Machine Base

Cast-Iron Fixed Bridge & Cast-Iron Columns, Increase Weight, Mass & Rigidity

Std. 12 Position, Aggregate Ready, Dynamic Automatic Rotary Tool Changer

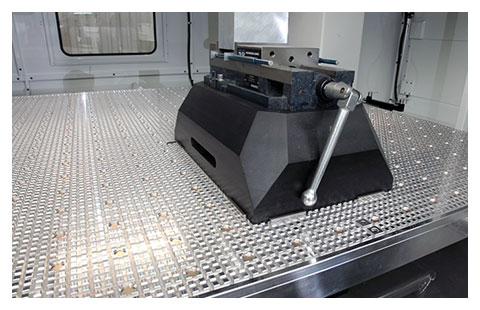

Twin Tables Can Operate Locked Together or Independently for Pendulum Processing

Compact Design Saves Valuable Shop Floor Space

Intelligent Design Allows for Easy and Loading and Unloading

C.R. Onsrud High-Flow Universal Vacuum Table System with Low Vacuum Sensing

Independently Controlled Vacuum Zones for Each Table

Comes Equipped with Choice of Flow Through or Dedicated Spoil Board

FANUC CNC Controller with Touch Screen HMI

4-Port Ethernet Connection, USB, and Serial Connectivity, for Easy Network Integration

Full 3D capability, Helical Interpolation, and Simultaneous 5-Axis Motion Standard

And many more options or accessories

SPECIFICATIONS

MODEL NUMBER F148CH Number of Axes 5+ Table Size 84” X 144” Z Clearance 49" X-Axis Travel 91” Y-Axis Travel 150” Z-Axis Travel 53" Approx. Footprint 27' X 16' Machining Speed 3600 ipm X & Y Rapid Traverse 3000 ipm Standard Spindle 15HP 24,000 rpm Tool Shank HSK 63F Standard Tool Capacity 15 Standard Vacuum Zones 2 MACHINE VIDEO

CONTROLLERS

ADDITIONAL PHOTOS