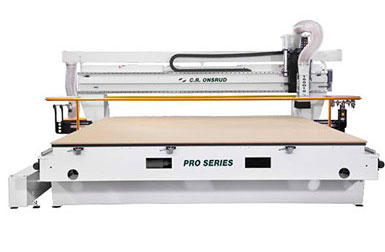

MOVING GANTRY STYLE CNC MACHINE

The one-piece, thick-wall steel base of the Wide Pro Series was specially engineered with internal steel reinforcements. It is designed to handle the extreme weight of large blocks of non-ferrous metal, oversized tooling or fixtures for composites, and sheet metal parts. You will be able to stack cut aluminum skins, or even the large and thick assemblies we tackle in the RV, marine, and aircraft industries. After being welded into a single structure, the machine base is heat treated and controlled cooled to create a stress free, normalized, and lasting machining platform. Then the precision machining for all of the critical components is accomplished in one set-up, with all of the operations performed on the same face, to guarantee machined-in accuracy and stability. This base also incorporates the top-rail design of the Pro Series which allows for shorter and stubbier one-piece steel vertical columns, which are more rigid and have more leverage over the bridge than other side rail designs. The result is a high precision machine that handles the largest workpieces, deals with the heaviest materials and tooling, offers unique automation and material handling options, and provides the best possible cost per table size relationship available.

WIDE PRO-SERIES

STANDARD FEATURES

Full 2 Year Warranty

Factory Provided 24/7/365 After Hours Emergency Tech Support

Factory Provided Onsite Machine Installation and Training

Factory Provided Advanced Technical & Applications Support

Factory Provided In Depth Remote Online Diagnostics

4-Pole, reversible, 24,000 RPM High Torque Spindle

HSK-63F Spindle Taper and Tool Holders, with 1 inch (25mm) collet capacity

Over 14 Inches of Z-Axis Clearance & 11 inches of Z-Axis stroke

Finite Element Analysis used in Engineering entire frame

FEA Engineered, Heavy-wall, All-Steel Bridge, Vertical Columns, & Table Support Base

Std. 12 Position, Aggregate Ready, Dynamic Automatic Rotary Tool Changer

Dual Support, Direct Drive, Independent Channel, Design Enhances Accuracy & Rigidity

Compact Design Saves Valuable Shop Floor Space

Intelligent Design Allows for Easy and Unrestricted Access to All Sides of the Machine

Efficient and Effective Integrated Dust Tranistion that Only Requires a 8 inch Dust Hose

C.R. Onsrud High-Flow Universal Vacuum Table System with Low Vacuum Sensing

3 Independently Controlled Vacuum Zones

Comes Equiped with Choice of Flow Through or Dedicated Spoil Board

Onsrud B&R Handheld CNC Controller with VNC PC Front Link (Other Controls Available)

4-Port Ethernet Connection, USB, and Serial Connectivity, for Easy Network Integration

Full 3D capability with Helical Interpolation

Tables Sizes in Excess of 60 feet long and up to 12 feet wide available

And many more options or accessories

SPECIFICATIONS

Model Number

6-Series

8-Series

10-Series

12-Series

3/4 3/4 3/4 3/4 ** ** ** ** 14" 14" 14" 14" ** ** ** ** 73” 97” 121” 145" 11” 11” 11” 11” ** ** ** ** 2500 ipm 2500 ipm 2500 ipm 2500 ipm 3500 ipm 3500 ipm 3500 ipm 3500 ipm 18HP 18HP 18HP 18HP 4-Pole 4-Pole 4-Pole 4-Pole 24,000 rpm 24,000 rpm 24,000 rpm 24,000 rpm HSK 63F HSK 63F HSK 63F HSK 63F 12 12 12 12 ** ** ** ** Number of Axes

Table Size

Z Clearance

X-Axis Travel

Y-Axis Travel

Z-Axis Travel

Approx. Footprint

Machining Speed

X & Y Rapid Traverse

Standard Spindle

Tool Shank

Standard Tool Capacity

Standard Vacuum Zones

Please Note: ** Size is dependent on machine length and configuration

MACHINE VIDEO

Coming Soon!

CONTROLLERS